Solutions

ALLSTREAM’s liquid waste disposal, treatment and management technologies are leading edge. ALLSTREAM’s proprietary methods and reagents reduce transportation and handling costs and reduce the environmental impact of disposal.

We take pride in providing customized solutions for liquid waste when our clients have a unique challenge. If your waste stream doesn’t have an ‘off the rack’ solution, we will be happy to work with you to develop a formula that better suits your needs

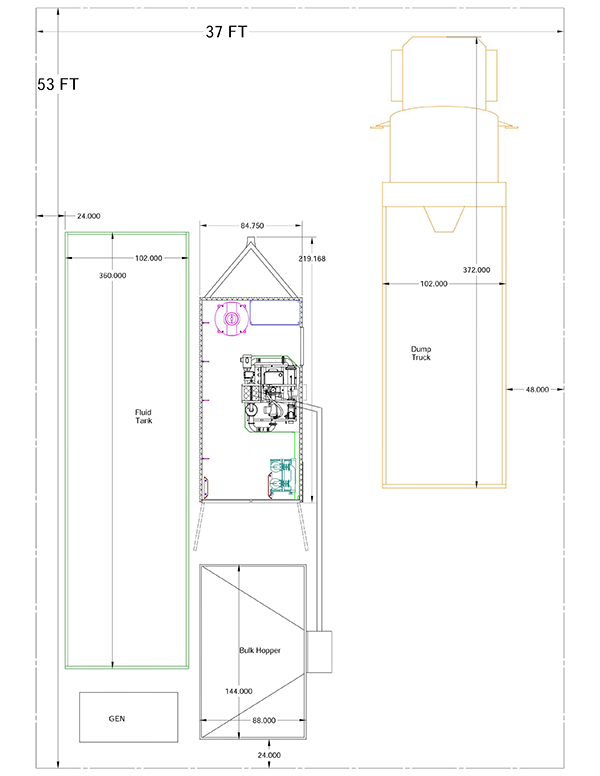

Our ALLSTREAM LMS 3 model for the treatment of liquid waste is available in gas, electric, diesel or hydraulic power sources.

Liquid Waste Disposal with the ALLSTREAM LMS 3